Celltrion's Commitment to Biopharmaceutical Excellence

2025.05.14

Celltrion has established itself as a leader in biopharmaceutical manufacturing, with a production capacity of 250,000 liters. With advanced animal cell culture technology and a flexible production system, we ensure a reliable supply of high-quality pharmaceuticals worldwide. By optimizing safety, stability, and cost competitiveness, we are committed to providing effective treatments to patients around the world.

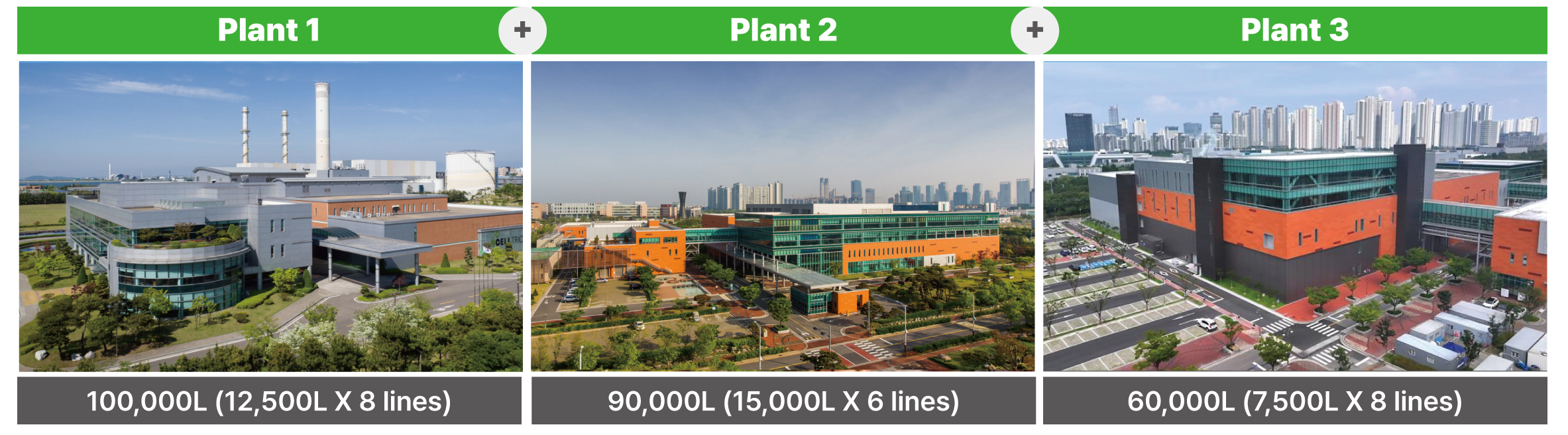

250,000 Liters of Production Capacity: A Global Competitive Edge

Our state-of-the-art production facilities in Songdo, Incheon, include three plants: Plant 1 (100,000 liters), Plant 2 (90,000 liters), and Plant 3 (60,000 liters). Together, these facilities have the capacity to produce 250,000 liters of monoclonal antibodies. The plants are designed to handle both large-scale production and flexible small-batch manufacturing, allowing us to meet the diverse needs of global markets, from commercial production to clinical trials. This adaptability in our production system is a significant competitive advantage, enabling us to swiftly respond to the evolving demands of the market.

Comprehensive Production System with Uncompromising Quality Assurance

Our integrated production system covers every step of the process—from raw material production and finished drug manufacturing to quality control, facility construction, and logistics management. This holistic approach ensures we maintain industry-leading production capabilities within South Korea while upholding the highest standards of safety and quality. Celltrion’s commitment to rigorous quality control and process management ensures that every phase of production meets the strictest standards.

Global Certifications and Advanced Production Facilities

Plant 1 was the first animal cell culture facility in Asia to receive FDA cGMP certification, and it is where the world’s first monoclonal antibody biosimilar, Remsima, was produced. It also features a 1,000L single-use bioreactor system, capable of handling small-batch production and clinical material manufacturing. This innovation demonstrates our advanced technological capabilities and commitment to excellence in quality control. Additionally, we are expanding our production capacity with a new finished drug manufacturing plant near Plant 1. Construction is underway, with the goal of completing the facility by the end of 2026. Commercial production is expected to begin in 2027, with the plant focusing on vial production for both existing and future products. This expansion is a key part of strengthening our global market presence.

Plant 2, established in 2011, is a large-scale production facility with a total capacity of 90,000 liters, featuring six 15,000-liter bioreactors. This facility enables the production of both drug substances and drug products, providing a major advantage over many companies that produce drug substances in-house but outsource the production of drug products. By managing both processes in-house, Plant 2 ensures significant cost savings, improved product quality, and enhanced operational efficiency and competitiveness.

▲ Plant 2 Bioreactor Hall

Plant 3 is specifically designed for next-generation biopharmaceutical production, featuring eight 7,500-liter bioreactors. Its flexible design allows for efficient production of various products and quick adaptation to changing market conditions and demand fluctuations. This facility will be essential to our long-term growth strategy, helping to maximize productivity and accelerate time-to-market for new products.

Setting a New Benchmark in Biopharmaceutical Manufacturing

As a global leader in both drug development and manufacturing, Celltrion stands out for its world-class production capacity and cutting-edge technology. We are committed to continuous innovation and investment, ensuring that we remain at the forefront of the global biopharmaceutical industry. Our ultimate goal is to provide better treatment options and improve patient outcomes worldwide.